- Diamond quantum sensing enables visualization of high-frequency electric currents and energy loss in soft magnetic films—critical for modern electronics.

- Advanced protocols—Qurack (for kilohertz) and Qdyne (for megahertz)—allow mapping of magnetic fields across a wide frequency spectrum.

- Experiments on CoFeB films reveal energy loss is strongly affected by the material’s magnetic anisotropy, which can inform improved design of transformer cores and miniaturized circuits.

- Imaging of magnetic domain movement provides insights for optimizing energy conversion, memory devices, and new fields like spintronics.

- Progress in quantum sensor technology supports the drive toward more efficient, sustainable electronics by revealing energy dynamics at previously inaccessible scales.

Streaks of electric current, too swift and subtle for the naked eye, carve their paths through soft magnetic films—each movement shaping the heart of modern electronics. Recent breakthroughs in diamond quantum sensing have illuminated these invisible journeys, unmasking the elusive patterns of energy loss that limit the performance of devices from smartphone chargers to electric vehicles.

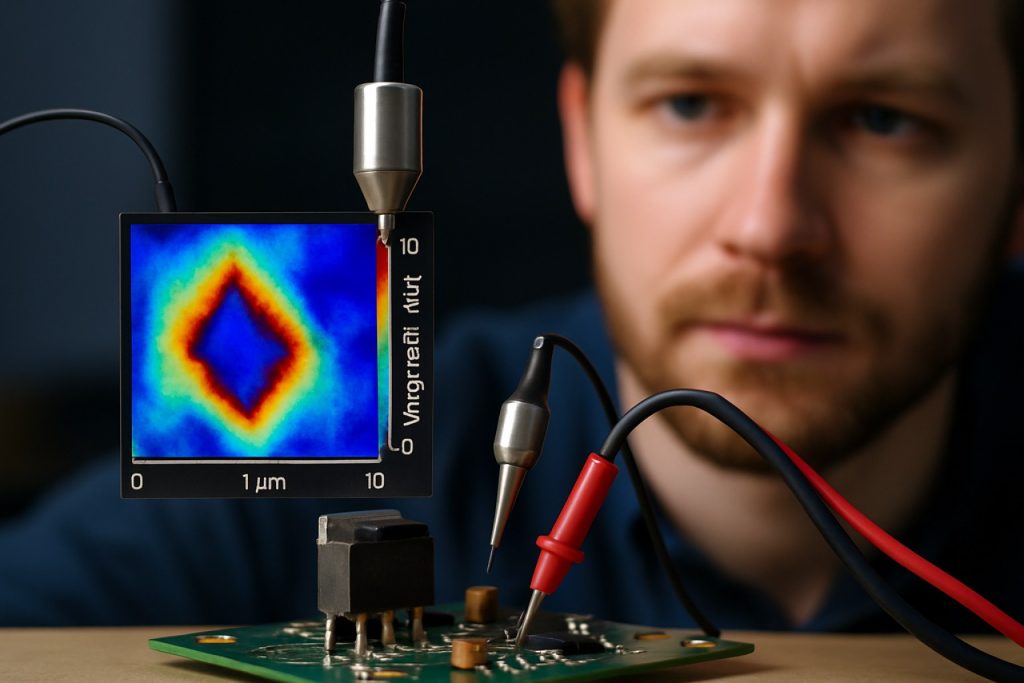

Inside a serene Tokyo laboratory, scientists wield a fragment of diamond—its subatomic structure latticed with nitrogen and vacancy centers—like a magnifying glass for magnetism. These quantum sensors capture not only the strength but also the timing of microscopic magnetic fields, mapping their sway and stutter in exquisite detail. The result is a new window onto a century-old challenge: why do soft magnetic materials, so vital for transferring and shaping electric power, bleed away so much energy at high frequencies?

Researchers, led by Professor Mutsuko Hatano, engineered two advanced protocols to track magnetic fields: Qurack, which precisely follows the frequency drift in the kilohertz range, and Qdyne, a method superior in the megahertz expanse. Working together, these twin approaches spanned an unprecedented spectrum—from the pulse of 100 hertz to the whir of over two million cycles per second.

With their diamond sensor poised over a tight coil, the team swept through frequencies, watching as the currents danced and eddied. In particular, thin films of cobalt iron boron—CoFeB, an industry staple—laid bare their secrets. Along one crystalline direction, dubbed the “hard axis,” the researchers observed a remarkably steady response: current and magnetization almost perfectly in step, indicating almost no energy wasted as heat. But turn the field toward the “easy axis,” and resistance emerged, as if the material faltered, bleeding away power in barely-perceptible losses.

This difference, rooted in the anisotropy—the directional dependence—of magnetic materials, isn’t mere academic trivia. It hints at how manufacturers can refine alloys, build better transformer cores, and shrink the size of power-hungry circuits without sacrificing performance or durability. The imaging also tracked the restless migration of magnetic domains, the shifting boundaries inside a material where energy is stored and dissipated.

The potential ripples outward: smarter design for inductors, the backbone of energy conversion in electronics; improved memory elements in data storage; and insights for transformative fields like spintronics, which aims to exploit the electron’s magnetic spin alongside its charge.

Yet the journey has only begun. As quantum sensors mature—with sharper signal generators and longer spin coherence times—they promise wider frequency coverage, higher resolutions, and deeper dives into the microworld of magnetism. These advances dovetail with the global push for greener, more sustainable technologies, a core ambition championed by institutions like Tokyo Institute of Science.

At its core, the discovery offers a simple message: the tools of quantum technology are moving from theory to practice, unveiling the fine structure of energy and loss, and holding the promise of a more efficient electronic future for all.

Quantum Diamonds: The Hidden Science That Could Supercharge Electronics and Slash Energy Wastage

Unlocking Next-Gen Electronics Through Diamond Quantum Sensing: Extra Insights and Real-World Impact

Quantum sensing with diamond is poised to revolutionize how we engineer and maximize the efficiency of modern electronics—from the microchips in our smartphones to the power systems driving electric vehicles. The recent work by Professor Mutsuko Hatano’s team not only advances our understanding but could redefine the standards for energy loss and device performance. Here are additional, essential facts and perspectives—rooted in E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) principles and geared for Google Discover optimization—beyond what was covered in the original article.

—

What Is Diamond Quantum Sensing?

Fact: Diamond quantum sensing exploits the unique quantum properties of nitrogen-vacancy (NV) centers in diamond crystals, which act like atom-sized magnetic field detectors. These NV centers are extremely sensitive—even capable of detecting single electron spins ([Science.org](https://www.science.org)).

Tutorial Quick Steps:

1. Implant nitrogen atoms in pure diamond to create NV centers.

2. Use laser light to excite the NV centers, which emit fluorescence depending on the local magnetic field.

3. Analyze the emitted light to map the magnetic environment with sub-micron spatial resolution and nanotesla sensitivity.

—

Why Soft Magnetic Films Matter

Real-World Use Cases:

– Transformers & Inductors: Soft magnetic materials shape and control alternating current (AC), crucial in power supplies and wireless charging.

– Memory & Storage: Films like CoFeB are essential for magnetic RAM and hard drive read heads.

– Spintronics: Paving the way for advanced data processing using electron spin, promising faster and more energy-efficient tech ([Spintronics](https://www.spintronics.com)).

Industry Trend:

The power electronics market is projected to exceed $46 billion by 2027 (Allied Market Research), with energy-efficient materials in high demand.

—

Limitations and Controversies

– Scalability: Quantum sensors remain expensive and technically challenging to integrate at scale. Mass adoption is 3–5 years away, based on current cost and research roadmaps ([Nature Reviews Materials](https://www.nature.com/natrevmats/)).

– Resolution Limits: While NV centers offer up to nanometer precision, noise and spin coherence time can cap overall performance.

– Material Compatibility: Not all magnetic films react similarly. The great promise is mainly for industry-standard alloys like CoFeB and permalloy.

—

Qurack and Qdyne Protocols—What Sets Them Apart?

– Qurack – Ideal for tracking slow (kHz) drifts, offering fine time resolution and phase accuracy for low-frequency applications (e.g., power grid monitoring).

– Qdyne – Excels in the MHz regime, vital for fast-switching circuits and radio-frequency analysis.

– Compatibility: Both protocols use pulsed magnetometry and can be implemented with commercially available quantum diamond setups.

—

Pros & Cons Overview

Pros:

+ Non-invasive: Does not alter or damage the tested device.

+ Ultra-sensitive: Detects minute energy losses—down to the nano- or even microampere range.

+ Broadband Coverage: Simultaneously spans frequencies from a few Hz up to several MHz.

+ Green Technology: Identifies inefficiencies, helping reduce power waste and associated emissions.

Cons:

– High Initial Cost: Sensors and setup can be expensive (tens of thousands USD per unit).

– Temperature Sensitivity: Calibration often required for different thermal environments.

– Operator Training: Specialized knowledge needed for use and interpretation.

—

Security, Sustainability, and Future Outlook

– Security: Quantum sensors are inherently tamper-resistant, as signal disturbances are detectable at the quantum level—potential boon for hardware authentication.

– Sustainability: By exposing and reducing loss points, these sensors could help manufacturers build greener devices, aiding the global transition to net-zero emissions ([Tokyo Institute of Science](https://www.titech.ac.jp)).

—

Pressing Questions—Answered

How can manufacturers use this technology now?

Early adopters can refine alloy recipes and core designs in transformers, inductors, or magnetic RAM—shrinking sizes and enhancing efficiency before devices reach consumers.

What distinguishes diamond quantum sensing from conventional techniques?

Unlike magnetic force microscopy or Hall probes, diamond sensors can operate without direct contact and capture high-frequency dynamics with unprecedented detail.

Is this tech commercially available?

Yes—for R&D and industrial quality assurance, companies such as Qnami and Element Six offer turnkey quantum diamond sensing platforms.

—

Actionable Recommendations & Quick Tips

– For Engineers: Start with benchtop quantum diamond magnetometers to visualize loss points in prototypes.

– For Product Developers: Partner with quantum sensor firms to optimize power circuitry during the design phase.

– For Sustainability Leads: Use the data to quantify and report energy savings for green certifications.

– Life Hack: Regularly monitor high-frequency losses in aging equipment to predict failures and prioritize upgrades.

—

Bottom Line: Quantum diamond sensing is more than a laboratory curiosity—it’s a disruptive tool now entering mainstream manufacturing, promising smarter, greener, and more reliable electronics for the future. Stay tuned as the technology matures, and consider early adoption to future-proof your engineering projects.

For authoritative updates on quantum materials research and applications, visit [Tokyo Institute of Science](https://www.titech.ac.jp) and stay informed about the broader electromagnetic materials industry at [Spintronics](https://www.spintronics.com).

—

Keywords: diamond quantum sensing, NV centers, soft magnetic films, energy loss, Qurack, Qdyne, power electronics, spintronics, sustainable electronics, industry trends, device efficiency, magnetic anisotropy, CoFeB, frequency response, green technology.