Unlocking the Power of Piezoresistive Sensors: How Advanced Materials Are Transforming Pressure and Force Detection Across Industries

- Introduction to Piezoresistive Sensing Principles

- Historical Evolution and Key Milestones

- Material Science: Silicon, Polymers, and Nanocomposites

- Design Architectures and Fabrication Techniques

- Performance Metrics: Sensitivity, Linearity, and Stability

- Integration with Modern Electronics and IoT

- Applications in Medical Devices and Healthcare

- Automotive and Industrial Use Cases

- Emerging Trends: Flexible and Wearable Piezoresistive Sensors

- Future Prospects and Research Directions

- Sources & References

Introduction to Piezoresistive Sensing Principles

Piezoresistive sensors are a class of devices that exploit the piezoresistive effect—an intrinsic property of certain materials where their electrical resistance changes in response to applied mechanical stress. This phenomenon is distinct from piezoelectricity, as it involves a change in resistance rather than the generation of an electric charge. The piezoresistive effect is most pronounced in semiconductors such as silicon, which has made these materials the cornerstone of modern piezoresistive sensor technology.

The fundamental principle behind piezoresistive sensors is straightforward: when a mechanical force, such as pressure, strain, or acceleration, is applied to a piezoresistive material, its atomic lattice deforms. This deformation alters the band structure and carrier mobility within the material, leading to a measurable change in electrical resistance. By integrating these materials into electrical circuits, the resistance change can be precisely monitored and correlated to the magnitude of the applied force.

Piezoresistive sensors are widely used in various applications, including pressure sensing, tactile sensing, and structural health monitoring. Their popularity stems from several advantages: high sensitivity, compatibility with microelectromechanical systems (MEMS) fabrication processes, and the ability to miniaturize devices for integration into complex systems. Silicon-based piezoresistive sensors, in particular, benefit from the mature semiconductor manufacturing infrastructure, enabling mass production with high reliability and repeatability. Organizations such as STMicroelectronics and Robert Bosch GmbH are prominent developers and manufacturers of MEMS-based piezoresistive sensors, supplying components for automotive, medical, and consumer electronics industries.

The operation of a typical piezoresistive sensor involves a Wheatstone bridge configuration, where piezoresistive elements are arranged to maximize sensitivity and compensate for temperature-induced resistance changes. When mechanical stress is applied, the resulting imbalance in the bridge produces a voltage output proportional to the force. This configuration enhances measurement accuracy and stability, which is critical in demanding environments such as automotive safety systems and industrial process control.

Research and standardization efforts by organizations like the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC) have contributed to the development of guidelines and performance benchmarks for piezoresistive sensors. These standards ensure interoperability, safety, and reliability across diverse applications, further cementing the role of piezoresistive sensing in modern technology.

Historical Evolution and Key Milestones

The historical evolution of piezoresistive sensors is closely intertwined with advances in materials science, semiconductor technology, and microfabrication. The piezoresistive effect—whereby the electrical resistance of a material changes under mechanical strain—was first observed in metals in the mid-19th century. However, the phenomenon gained significant technological relevance in the 1950s when researchers discovered that semiconductors such as silicon and germanium exhibited a much stronger piezoresistive response than metals. This discovery laid the foundation for the development of highly sensitive strain gauges and pressure sensors.

A pivotal milestone occurred in 1954, when C.S. Smith at Bell Telephone Laboratories published seminal work on the piezoresistive properties of silicon and germanium, demonstrating their potential for sensor applications. This breakthrough coincided with the rapid growth of the semiconductor industry, enabling the integration of piezoresistive elements into microelectronic devices. The 1960s saw the first commercial piezoresistive pressure sensors, which leveraged silicon’s compatibility with photolithography and etching techniques, allowing for miniaturization and mass production.

The 1970s and 1980s marked the era of microelectromechanical systems (MEMS), with organizations such as STMicroelectronics and Texas Instruments pioneering the integration of piezoresistive sensors into compact, robust, and cost-effective devices. MEMS technology enabled the fabrication of complex sensor structures on silicon wafers, dramatically expanding the range of applications—from automotive and aerospace to medical devices and consumer electronics.

Key milestones in the 1990s and 2000s included the development of high-performance piezoresistive accelerometers and pressure sensors for safety-critical systems, such as automotive airbag deployment and industrial process control. The adoption of advanced materials, including polysilicon and silicon-on-insulator (SOI) substrates, further improved sensor stability, sensitivity, and reliability. Leading research institutions and industry consortia, such as imec (a prominent microelectronics research center), contributed to innovations in sensor design and fabrication.

In recent years, the evolution of piezoresistive sensors has been characterized by the integration of wireless communication, energy harvesting, and flexible substrates, enabling new applications in wearable technology and the Internet of Things (IoT). Organizations like Bosch have played a significant role in commercializing MEMS-based piezoresistive sensors for mass-market applications, underscoring the enduring impact of this technology on modern sensing solutions.

Material Science: Silicon, Polymers, and Nanocomposites

Piezoresistive sensors are a cornerstone of modern sensing technology, leveraging the change in electrical resistance of materials under mechanical stress to detect force, pressure, or strain. The material science underpinning these sensors is critical to their performance, reliability, and application range. Three primary material classes dominate the field: silicon, polymers, and nanocomposites.

Silicon is the most established material for piezoresistive sensors, especially in microelectromechanical systems (MEMS). Its crystalline structure exhibits a pronounced piezoresistive effect, making it highly sensitive to mechanical deformation. Silicon’s compatibility with standard semiconductor fabrication processes allows for precise miniaturization and integration with electronic circuits. This has led to widespread adoption in automotive, medical, and industrial applications. Organizations such as STMicroelectronics and Bosch have been instrumental in advancing silicon-based MEMS sensors, offering robust solutions for pressure and acceleration sensing.

Polymers offer a contrasting set of properties. While their intrinsic piezoresistive effect is generally weaker than that of silicon, polymers provide exceptional flexibility, low cost, and ease of processing. Conductive polymers, such as polyaniline and polypyrrole, can be engineered to enhance their piezoresistive response. These materials are particularly attractive for wearable electronics, soft robotics, and biomedical devices, where conformability and biocompatibility are essential. Research institutions and companies, including imec, a leading nanoelectronics research center, are actively developing polymer-based sensor technologies for next-generation flexible devices.

Nanocomposites represent a rapidly evolving frontier in piezoresistive sensor materials. By embedding conductive nanomaterials—such as carbon nanotubes, graphene, or metallic nanoparticles—into polymer matrices, researchers can dramatically enhance sensitivity and tailor mechanical properties. These hybrid materials combine the flexibility of polymers with the superior electrical and mechanical characteristics of nanomaterials. The result is sensors with high sensitivity, stretchability, and durability, suitable for applications ranging from electronic skin to structural health monitoring. Organizations like National Institute of Standards and Technology (NIST) are at the forefront of standardizing and characterizing nanocomposite materials for sensor applications.

In summary, the choice of material—silicon for precision and integration, polymers for flexibility, and nanocomposites for advanced performance—defines the capabilities and application domains of piezoresistive sensors. Ongoing research and development by leading organizations continue to expand the possibilities for these versatile devices.

Design Architectures and Fabrication Techniques

Piezoresistive sensors are widely utilized for their ability to convert mechanical stress into a measurable change in electrical resistance. The design architectures and fabrication techniques of these sensors have evolved significantly, enabling their integration into diverse applications such as pressure sensing, tactile interfaces, and biomedical devices.

The fundamental architecture of a piezoresistive sensor typically consists of a substrate—commonly silicon—onto which piezoresistive elements are deposited or diffused. The most prevalent configuration is the Wheatstone bridge, which enhances sensitivity and compensates for temperature variations. In this arrangement, four piezoresistive elements are connected in a diamond-shaped circuit, allowing for differential measurement and improved signal-to-noise ratio. The placement and orientation of these elements are critical, as the piezoresistive effect is highly anisotropic in crystalline materials like silicon.

Microelectromechanical systems (MEMS) technology has revolutionized the fabrication of piezoresistive sensors. MEMS-based sensors are typically manufactured using standard semiconductor processes such as photolithography, ion implantation, and etching. These techniques allow for precise control over the geometry and doping concentration of the piezoresistive elements, which directly influence sensor performance. Bulk micromachining and surface micromachining are two primary approaches: the former involves etching away large portions of the substrate to form diaphragms or cantilevers, while the latter builds up structures layer by layer on the substrate surface.

Material selection is another crucial aspect of sensor design. While single-crystal silicon remains the dominant material due to its excellent piezoresistive properties and compatibility with integrated circuit fabrication, alternative materials such as polysilicon, silicon carbide, and even nanomaterials like graphene and carbon nanotubes are being explored for specialized applications. These materials can offer enhanced sensitivity, flexibility, or chemical resistance, broadening the operational range of piezoresistive sensors.

Packaging and integration are also vital considerations. The sensor die must be protected from environmental factors while maintaining mechanical coupling to the measurand. Advanced packaging techniques, including wafer-level packaging and hermetic sealing, are employed to ensure reliability and longevity, especially in harsh environments such as automotive or industrial settings.

Organizations such as STMicroelectronics and Robert Bosch GmbH are leaders in the development and mass production of MEMS-based piezoresistive sensors, leveraging their expertise in semiconductor processing and sensor integration. Research institutions and standardization bodies like the Institute of Electrical and Electronics Engineers (IEEE) also play a significant role in advancing design methodologies and fabrication standards for these devices.

Performance Metrics: Sensitivity, Linearity, and Stability

Piezoresistive sensors are widely utilized in various applications due to their ability to convert mechanical stress into a measurable change in electrical resistance. The performance of these sensors is primarily evaluated based on three critical metrics: sensitivity, linearity, and stability. Understanding these parameters is essential for optimizing sensor design and ensuring reliable operation in fields such as automotive, biomedical, and industrial automation.

Sensitivity refers to the sensor’s ability to detect small changes in applied force or pressure. It is typically defined as the ratio of the change in electrical resistance to the applied mechanical stimulus. High sensitivity is crucial for applications requiring the detection of minute forces, such as tactile sensing in robotics or physiological monitoring in healthcare. The sensitivity of piezoresistive sensors depends on factors such as the material’s gauge factor, geometry, and the quality of the electrical contacts. Silicon-based piezoresistive sensors, for example, are known for their high gauge factors, making them suitable for precision measurements (STMicroelectronics).

Linearity describes how closely the sensor’s output follows a straight-line relationship with the applied stimulus. High linearity ensures that the sensor’s response is predictable and proportional across its operating range, which is vital for accurate signal interpretation and calibration. Nonlinear behavior can introduce errors, complicating data analysis and reducing measurement accuracy. Manufacturers such as Honeywell and Analog Devices emphasize linearity in their piezoresistive sensor designs to meet the stringent requirements of industrial and medical applications.

Stability encompasses the sensor’s ability to maintain consistent performance over time and under varying environmental conditions. This includes resistance to drift, hysteresis, and degradation due to temperature fluctuations, humidity, or mechanical fatigue. Long-term stability is particularly important in safety-critical systems, such as automotive braking or aerospace instrumentation. Leading organizations like National Institute of Standards and Technology (NIST) provide guidelines and standards for evaluating sensor stability, ensuring that devices meet rigorous reliability criteria.

In summary, the performance of piezoresistive sensors is determined by their sensitivity, linearity, and stability. Advances in materials science, microfabrication, and packaging continue to enhance these metrics, enabling broader adoption and improved reliability in demanding applications. Ongoing research and standardization efforts by industry leaders and scientific organizations further support the development of high-performance piezoresistive sensing technologies.

Integration with Modern Electronics and IoT

Piezoresistive sensors, which operate by changing their electrical resistance in response to applied mechanical stress, have become integral components in the evolution of modern electronics and the Internet of Things (IoT). Their inherent advantages—such as high sensitivity, miniaturization potential, and compatibility with semiconductor fabrication processes—make them particularly suitable for integration into a wide array of electronic devices and smart systems.

In the context of modern electronics, piezoresistive sensors are widely used in microelectromechanical systems (MEMS), where their small size and low power consumption are critical. MEMS-based piezoresistive sensors are commonly found in smartphones, wearable devices, and automotive systems, enabling functionalities such as pressure sensing, tactile feedback, and structural health monitoring. The compatibility of piezoresistive materials, such as doped silicon, with standard CMOS (complementary metal-oxide-semiconductor) processes allows for seamless integration with on-chip signal processing circuits, further enhancing their utility in compact and multifunctional electronic systems. Organizations like STMicroelectronics and Bosch have been at the forefront of developing MEMS sensors that leverage piezoresistive effects for consumer and industrial applications.

The proliferation of IoT has further amplified the demand for piezoresistive sensors, as these devices are essential for enabling real-time data acquisition and feedback in connected environments. Piezoresistive sensors are deployed in smart homes, industrial automation, healthcare monitoring, and environmental sensing, where they provide critical data on parameters such as pressure, force, and strain. Their ability to deliver accurate and reliable measurements, even in miniaturized and flexible formats, supports the development of distributed sensor networks that form the backbone of IoT ecosystems. For example, in healthcare, piezoresistive sensors are integrated into wearable patches and smart textiles to monitor physiological signals, contributing to personalized medicine and remote patient monitoring initiatives led by organizations such as imec, a leading research and innovation hub in nanoelectronics and digital technologies.

Furthermore, advances in materials science and nanotechnology are expanding the capabilities of piezoresistive sensors, enabling their integration with flexible substrates and wireless communication modules. This paves the way for next-generation IoT devices that are not only highly sensitive and robust but also conformable and energy-efficient. As the IoT landscape continues to evolve, the role of piezoresistive sensors in bridging the physical and digital worlds is expected to grow, driven by ongoing research and development from both industry leaders and academic institutions.

Applications in Medical Devices and Healthcare

Piezoresistive sensors have become integral components in a wide range of medical devices and healthcare applications due to their high sensitivity, compact size, and compatibility with microfabrication technologies. These sensors operate on the principle that their electrical resistance changes in response to applied mechanical stress, enabling precise measurement of pressure, force, and strain. Their versatility and reliability have led to widespread adoption in both invasive and non-invasive medical technologies.

One of the most prominent applications of piezoresistive sensors in healthcare is in blood pressure monitoring. Disposable piezoresistive pressure sensors are commonly used in invasive arterial and venous pressure monitoring systems, providing real-time, accurate measurements critical for patient management in intensive care units and during surgical procedures. Their small form factor allows integration into catheters and other minimally invasive devices, reducing patient discomfort and risk of infection. Leading medical device manufacturers, such as Medtronic and Smiths Medical, incorporate piezoresistive sensor technology in their pressure monitoring solutions.

Piezoresistive sensors are also widely used in respiratory care devices, including ventilators and spirometers. In these applications, the sensors monitor airway pressure and flow, enabling precise control of ventilation parameters and ensuring patient safety. Their rapid response time and stability under varying environmental conditions make them suitable for continuous monitoring in critical care settings. Organizations such as Philips and GE HealthCare utilize piezoresistive sensors in their respiratory support systems.

Another significant application is in wearable health monitoring devices. Flexible piezoresistive sensors, often fabricated using advanced materials like silicon or polymer composites, are integrated into smart patches, wristbands, and textiles to monitor physiological parameters such as pulse, respiration rate, and body movement. These sensors enable continuous, non-invasive health tracking, supporting early detection of medical conditions and personalized healthcare. Research institutions and companies, including Stanford University and Abbott, are actively developing next-generation wearable devices leveraging piezoresistive sensing technology.

In addition, piezoresistive sensors are employed in medical robotics and prosthetics, where they provide tactile feedback and force sensing capabilities. This enhances the dexterity and safety of robotic surgical instruments and improves the functionality of prosthetic limbs. The adaptability of piezoresistive sensors to various form factors and their compatibility with sterilization processes further support their integration into diverse medical applications.

Automotive and Industrial Use Cases

Piezoresistive sensors, which operate by changing their electrical resistance in response to applied mechanical stress, have become integral components in both automotive and industrial sectors. Their ability to provide accurate, real-time measurements of pressure, force, and strain makes them highly valuable for a wide range of applications.

In the automotive industry, piezoresistive sensors are extensively used for monitoring and controlling critical parameters to enhance safety, efficiency, and performance. One of the most prominent applications is in engine management systems, where these sensors measure manifold absolute pressure (MAP) and fuel rail pressure, enabling precise fuel injection and combustion control. This contributes to improved fuel efficiency and reduced emissions. Additionally, piezoresistive sensors are employed in tire pressure monitoring systems (TPMS), which are mandated in many regions to ensure vehicle safety by alerting drivers to under-inflated tires. Airbag deployment systems also rely on these sensors to detect rapid deceleration or impact, triggering timely inflation of airbags to protect occupants. Major automotive suppliers such as Bosch and Continental have developed advanced piezoresistive sensor solutions tailored for these applications.

Beyond passenger vehicles, piezoresistive sensors are crucial in heavy-duty and off-road vehicles, where they monitor hydraulic pressures in braking and steering systems, ensuring operational reliability under demanding conditions. Their robustness and ability to function in harsh environments make them suitable for such applications.

In industrial settings, piezoresistive sensors are widely used for process control, automation, and safety monitoring. They are commonly found in pressure transducers and transmitters that monitor fluid and gas pressures in pipelines, reactors, and storage tanks. This real-time data is essential for maintaining optimal process conditions and preventing hazardous situations. Industries such as oil and gas, chemical processing, and water treatment rely on these sensors for their accuracy and durability. Companies like Honeywell and Sensata Technologies are recognized for their industrial-grade piezoresistive sensor offerings.

Furthermore, piezoresistive sensors are integral to predictive maintenance strategies. By embedding these sensors in machinery, operators can continuously monitor stress and strain on critical components, enabling early detection of wear or failure. This approach minimizes downtime and extends equipment lifespan, which is particularly valuable in manufacturing and energy production environments.

Overall, the versatility, reliability, and scalability of piezoresistive sensors have established them as foundational elements in both automotive and industrial domains, supporting advancements in safety, efficiency, and automation.

Emerging Trends: Flexible and Wearable Piezoresistive Sensors

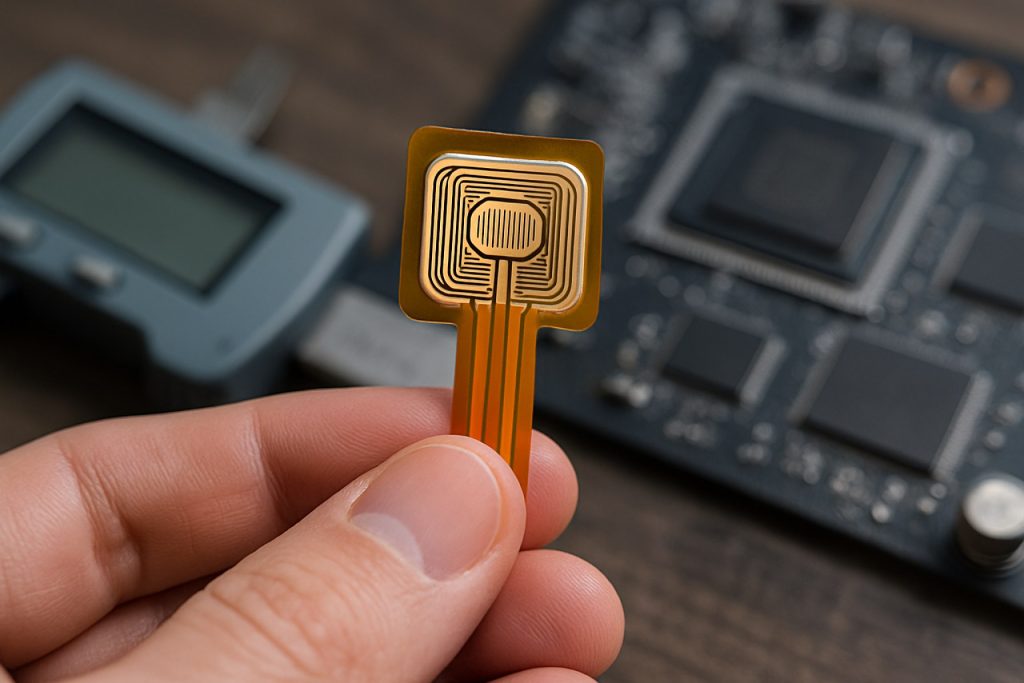

The field of piezoresistive sensors is undergoing a significant transformation with the advent of flexible and wearable technologies. Traditional piezoresistive sensors, which operate by changing their electrical resistance in response to applied mechanical stress, have long been used in industrial, automotive, and medical applications. However, recent advances in materials science and microfabrication are enabling the development of sensors that are not only highly sensitive but also flexible, stretchable, and suitable for integration with the human body or soft robotics.

Flexible piezoresistive sensors are typically fabricated using novel materials such as conductive polymers, carbon nanotubes, graphene, and metallic nanowires embedded in elastomeric substrates. These materials impart mechanical flexibility and conformability, allowing the sensors to maintain performance even when bent, stretched, or twisted. This is a crucial attribute for wearable applications, where sensors must adapt to the dynamic and irregular surfaces of skin or textiles. Research institutions and organizations such as the Nature Publishing Group and IEEE have documented significant progress in the development and characterization of these materials for next-generation sensor platforms.

Wearable piezoresistive sensors are finding applications in health monitoring, sports performance tracking, and human-machine interfaces. For example, flexible sensors can be integrated into smart clothing to monitor physiological signals such as respiration, heart rate, and joint movement. In healthcare, these sensors enable continuous, non-invasive monitoring of patients, providing real-time data for early diagnosis and personalized treatment. The National Institutes of Health (NIH) has supported research into wearable sensor systems for remote patient monitoring, emphasizing their potential to transform healthcare delivery.

Another emerging trend is the integration of piezoresistive sensors with wireless communication modules and energy-harvesting systems, paving the way for fully autonomous, battery-free wearable devices. Organizations like the Interuniversity Microelectronics Centre (imec), a leading research and innovation hub in nanoelectronics and digital technologies, are actively developing such integrated systems for smart health and IoT applications.

Despite these advances, challenges remain in ensuring long-term stability, biocompatibility, and large-scale manufacturability of flexible piezoresistive sensors. Ongoing research is focused on improving material durability, developing scalable fabrication techniques, and enhancing sensor sensitivity and selectivity. As these challenges are addressed, flexible and wearable piezoresistive sensors are poised to play a pivotal role in the future of personalized healthcare, soft robotics, and ubiquitous sensing environments.

Future Prospects and Research Directions

The future of piezoresistive sensors is marked by rapid advancements in materials science, device miniaturization, and integration with emerging technologies. As the demand for highly sensitive, flexible, and reliable sensors grows across sectors such as healthcare, robotics, automotive, and consumer electronics, research is increasingly focused on overcoming current limitations and unlocking new functionalities.

One major research direction involves the development of novel materials to enhance sensitivity, flexibility, and durability. Traditional silicon-based piezoresistive sensors, while well-established, face challenges in applications requiring mechanical flexibility or biocompatibility. To address this, researchers are exploring nanomaterials such as carbon nanotubes, graphene, and conductive polymers, which offer superior mechanical properties and tunable electrical characteristics. These materials enable the fabrication of flexible and stretchable sensors suitable for wearable devices and soft robotics, expanding the application landscape significantly.

Another promising avenue is the integration of piezoresistive sensors with microelectromechanical systems (MEMS) technology. MEMS-based piezoresistive sensors benefit from batch fabrication, miniaturization, and low power consumption, making them ideal for large-scale deployment in the Internet of Things (IoT) and smart environments. Organizations such as imec, a leading research and innovation hub in nanoelectronics and digital technologies, are actively developing next-generation MEMS sensors with enhanced performance and multifunctionality.

In the biomedical field, the future of piezoresistive sensors is closely tied to the development of implantable and wearable health monitoring systems. Research is focused on creating biocompatible, ultra-thin sensors capable of real-time physiological monitoring, such as blood pressure, pulse, and respiratory rate. The integration of wireless communication and energy harvesting technologies is also a key area, aiming to enable long-term, maintenance-free operation of these sensors in clinical and home settings.

Standardization and reliability remain critical challenges as piezoresistive sensors move toward widespread adoption in safety-critical applications, such as automotive and aerospace. Organizations like the International Organization for Standardization (ISO) and IEEE are expected to play pivotal roles in establishing testing protocols and performance benchmarks to ensure sensor reliability and interoperability.

Looking ahead, the convergence of artificial intelligence (AI) and advanced signal processing with piezoresistive sensor technology is anticipated to enable smarter, self-calibrating systems capable of complex data interpretation. This will further drive innovation in fields ranging from human-machine interfaces to environmental monitoring, solidifying the role of piezoresistive sensors in the next generation of intelligent systems.

Sources & References

- STMicroelectronics

- Robert Bosch GmbH

- Institute of Electrical and Electronics Engineers (IEEE)

- Texas Instruments

- imec

- National Institute of Standards and Technology (NIST)

- Honeywell

- Analog Devices

- Medtronic

- Philips

- GE HealthCare

- Stanford University

- Nature Publishing Group

- National Institutes of Health (NIH)

- International Organization for Standardization (ISO)